1. Cutting accuracy: High precision cutting machines can ensure smooth cutting edges and reduce defects, but the price is relatively high. Therefore, the requirement for accuracy needs to be determined based on specific application scenarios and product quality requirements

2. Cutting speed: Some advanced machine designs can quickly complete cutting, but the price will also increase accordingly. Therefore, it is necessary to find a balance between cutting speed and cost

3. Durability: Good manufacturing quality and regular maintenance can extend the service life of the machine. Therefore, when choosing, it is necessary to consider the durability and reliability of the machine

4. Difficulty level of operation: The operation of a fully automatic glass cutting machine should be as simple as possible to facilitate employees to quickly get started and reduce training costs and time

5. Adaptability: Due to the variety of installation or glass requirements, as well as the diverse sizes needed, it is necessary to choose machinery that can flexibly operate the size to adapt to different glass size requirements

6. Safety: The safety of mechanical equipment is the basic principle for enterprises to purchase equipment. It is necessary to ensure that the equipment is designed with consideration for the safety of operators and to avoid potential safety hazards.

7. Actual needs: Firstly, it is necessary to clarify one's actual production needs, including production characteristics, requirements, and the properties of the materials being produced, in order to select a glass cutting machine that can meet these needs

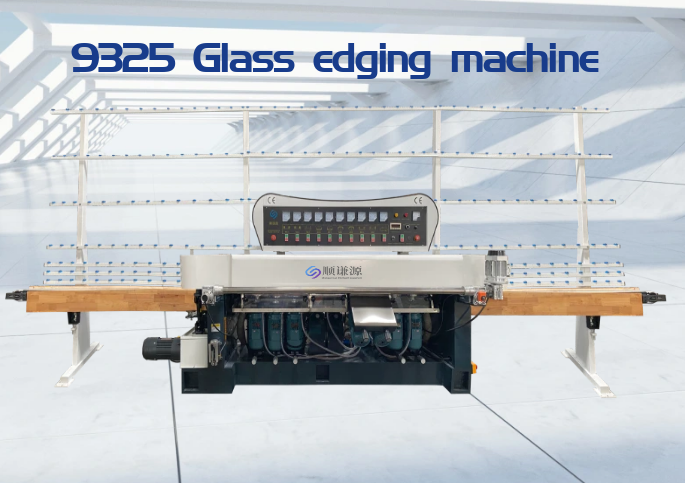

The key to using a glass edging machine correctly is to follow a series of operating steps and precautions to ensure processing quality and equipment safety

English

English