261 glass beveling machine

Min size:30x30mm

Bevel angle:0-35°

Glass thickness:3-19mm

Feeding speed:0.5-7m/min

Max bevel width:40mm

Weight of machine:About 3800T

Overall size(LxWxH):6800x1300x2500mm

Power:About 23kw

voltage:380V/50HZ

Min size:30x30mm

Bevel angle:0-35°

Glass thickness:3-19mm

Feeding speed:0.5-7m/min

Max bevel width:40mm

Weight of machine:About 3800T

Overall size(LxWxH):6800x1300x2500mm

Power:About 23kw

voltage:380V/50HZ

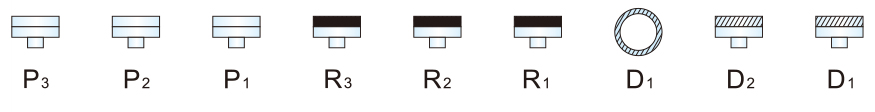

Position of Wheels:

Feature And Function:

This machine adopts PLC control to adjust the thickness, angle, and height of glass processing with one click. This inclined surface machine is suitable for grinding straight inclined surfaces and bottom edges of flat glass. Rough grinding, fine grinding, beveled edge polishing, and bottom edge grinding are completed in one processing. The polishing effect is consistent with the mirror surface. The front crossbeam and grinding motor can be adjusted simultaneously. The front pressure plate has a lifting adjustment system that can be adjusted according to the size of the glass. The rear pressure plate is made of thickened steel plate, which has strong rigidity, smooth transmission, and high processing accuracy; Adopting continuously variable transmission, the processing speed can be adjusted arbitrarily, the operation is simple, and the practicality is strong.

1. High Precision Processing: It has nine motors for fine beveling and polishing. Ensures that the edges of the glass are always finished correctly with exactness.

2. Versatile Beveling Capabilities: Can process glasses with varying thicknesses and sizes. Different bevel widths and angles are allowed.

3. Advanced Control System: An easy to use digital control interface. Allowing for easy operation and changes in parameters.

4. High-Speed Operation: This machine prioritizes quality over speed but still performs efficiently at a fast pace. Reduces production time by working quickly without reducing quality or accuracy thereby making the process more efficient overall.

1. Architectural Glass: The machine is fit for beveling windows, doors, façades and other architectural glasses. It contributes to both the beauty and strength of buildings.

2. Furniture Glass: The table tops, shelf fronts and decorative pieces are some of the furniture glass that it processes. For safety and eye catching finishing.

3. Mirrors: This kind of machine is used to gives the mirrors in this case a good look related to various places like bathrooms, dressing rooms, etc. A good finish for better reflecting surfaces.

4. Automotive Glass: Those which makes vehicle glass components can also use this type of machine too. They conform to high-quality standards as expected by an automotive industry.

This machine is versatile and can handle a variety of glass types, including flat glass, tempered glass, laminated glass, and low-e glass, making it suitable for diverse applications.

The machine is equipped with advanced control systems and high-quality motors that ensure consistent speed and pressure during the beveling process, resulting in uniform and high-quality finishes on all glass edges.

Regular maintenance includes cleaning the machine, checking the alignment of the motors, and ensuring that all moving parts are well-lubricated. Detailed maintenance instructions are provided in the user manual.

Yes, the machine is designed to accommodate large glass panels. It has a robust frame and powerful motors that can handle the weight and size of large glass pieces, ensuring precise beveling.

The machine comes with multiple safety features, including emergency stop buttons, protective covers, and sensors that prevent accidental operation and ensure the safety of the operator.